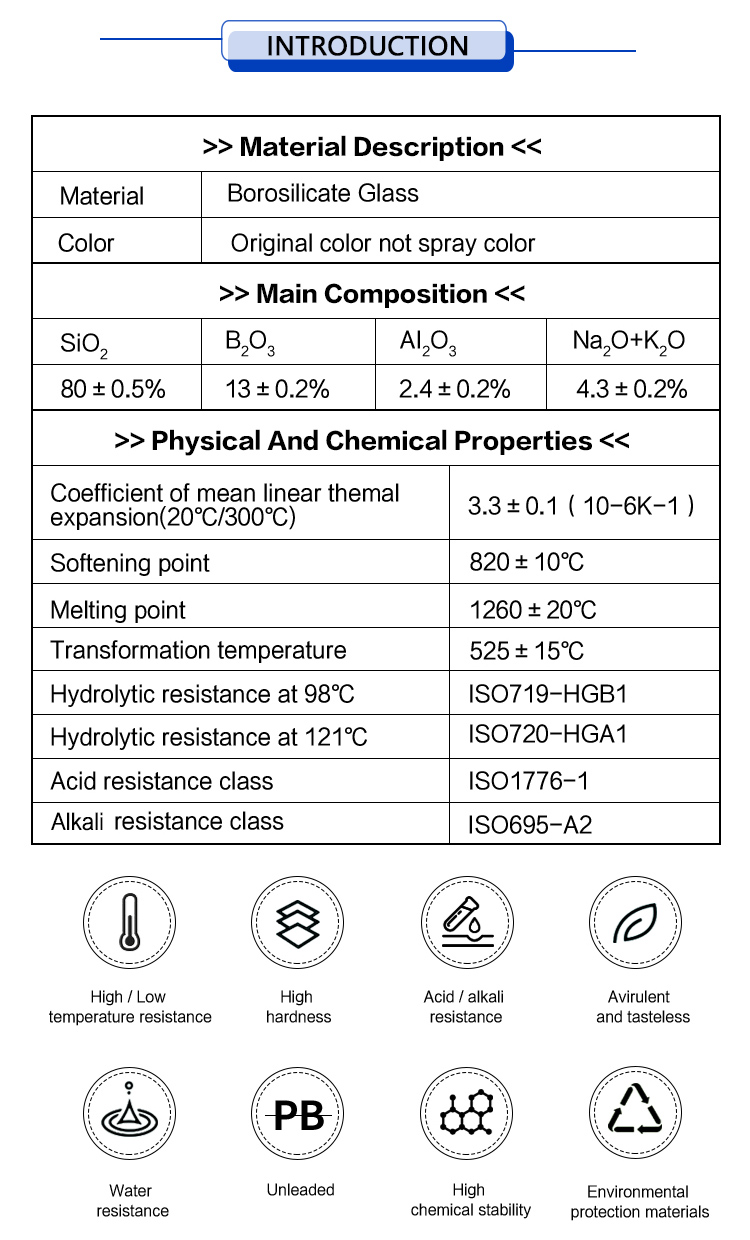

Features of borosilicate tubing include:

- Thermal Resistance: Borosilicate glass has excellent thermal resistance, making it capable of withstanding high temperatures without significant expansion or contraction. This property is particularly important in applications involving rapid temperature changes or extreme heat, such as in laboratory glassware.

- Chemical Resistance: Borosilicate glass is highly resistant to attack by most chemicals, including acids, bases, and organic solvents. This property makes it suitable for a wide range of chemical and laboratory applications.

- Low Thermal Expansion: Borosilicate glass has a low coefficient of thermal expansion, which means it expands and contracts less with changes in temperature compared to regular soda-lime glass. This property minimizes the risk of thermal stress and breakage.

- Durability: Borosilicate tubing is durable and less prone to breakage compared to regular glass. It can withstand mechanical stress and is less likely to shatter upon impact.

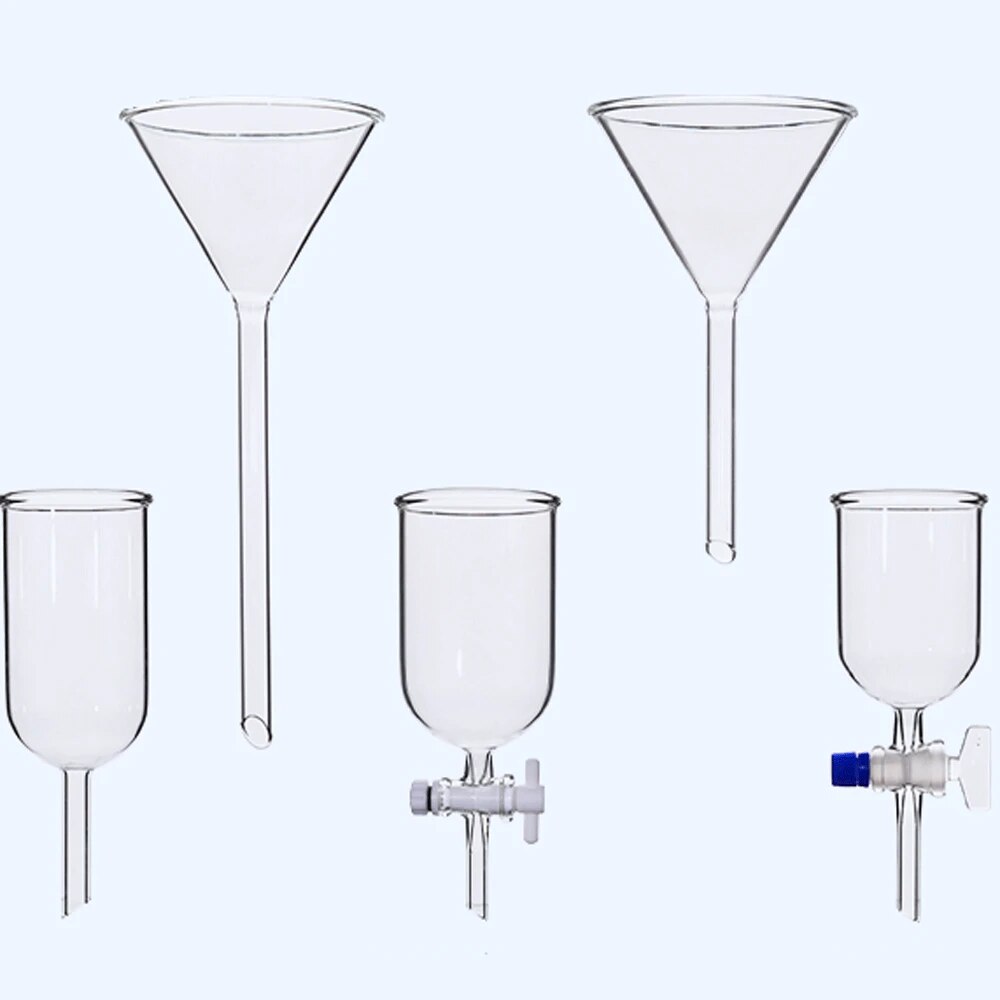

These features make borosilicate tubing a versatile material for a wide range of applications, from laboratory glassware and chemical apparatus to industrial equipment, lighting, and more.

Borosilicate tubing offer several advantages, including:

- Clarity and Transparency: Borosilicate glass is highly transparent, allowing for excellent visibility of the contents within the tubing. This is important in applications where visual observation is necessary, such as in laboratory experiments and industrial processes.

- Electrical Insulation: Borosilicate glass is an excellent electrical insulator, making it suitable for electrical applications where high resistance to electrical current is required.

- Biocompatibility: It is biocompatible and non-reactive with bodily fluids, making it suitable for medical and pharmaceutical applications like syringes and implants.

- Hydrolytic Resistance: Its resistance to water and moisture makes it ideal for applications where prolonged contact with liquids is necessary, such as in pharmaceutical packaging.

These advantages make borosilicate tubing a versatile and reliable material for a wide range of industries and applications, from laboratory and scientific equipment to chemical processing, lighting, and more.

Customizable aspects of borosilicate tubing include:

- Size and Dimensions: Borosilicate tubing can be manufactured in various sizes and dimensions, allowing for customization to fit specific applications. This includes variations in outer diameter, inner diameter, and wall thickness.

- Shape: Borosilicate tubing can be bent, curved, or shaped into custom configurations to accommodate specific design requirements. Custom shapes are often used in scientific glassware, industrial equipment, and artistic glasswork.

- Cut Length: The length of borosilicate tubing can be customized to match the desired specifications. Tubes can be cut to the required length to fit within a particular system or structure.

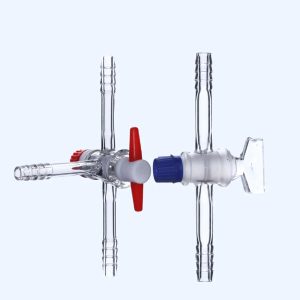

- End Closures: Borosilicate tubing can have customized end closures, such as flanges, ground glass joints, or threaded connections, to facilitate connections with other components or systems.

- Surface Finish: The surface finish of borosilicate tubing can be customized. It can be left as-is with a smooth finish or further processed to achieve a specific texture or finish, depending on the application.

- Markings and Graduations: Borosilicate tubing can be customized with markings, graduations, or labels for measurement or identification purposes. These are commonly used in laboratory glassware and industrial processes.

Customization of borosilicate tubing is common in industries like pharmaceuticals, chemicals, optics, and glass art, where precise specifications are essential for the success of the project. Manufacturers and suppliers often work closely with customers to provide tailored solutions that meet their specific needs.

There are several packaging solutions available for borosilicate tubing, including:

- Individual Packaging: Each borosilicate tube is individually wrapped or placed in its own protective sleeve. This method provides extra protection and is commonly used for high-precision and fragile glass items.

- Bulk Packaging: Multiple borosilicate tubes are bundled together without individual wrapping. Bulk packaging is more cost-effective but may require additional precautions to prevent breakage during handling.

- Cardboard Tubes: Tubes can be packaged in cardboard or paper tubes with protective caps on both ends. These cardboard tubes are often used for short-length borosilicate tubes.

- Plastic or Foam Inserts: Tubes can be placed in foam or plastic inserts within a larger container to prevent movement and minimize the risk of damage.

- Wooden Crates: For larger or heavier borosilicate tubes, wooden crates can be used to protect the glass during transportation. These crates provide excellent protection against impacts and environmental factors.

- Plastic or PVC Tubes: Some borosilicate tubes are packaged in transparent plastic or PVC tubes, allowing for easy visibility and inspection without removing the tube from its protective container.

The choice of packaging depends on factors such as the size and length of the borosilicate tubes, their fragility, the shipping method, and the specific requirements of the application. Ensuring that the glass is well-protected during storage and transportation is crucial to prevent damage and maintain its quality.