Features of borosilicate glass container include:

- Thermal resistance: Borosilicate glass has excellent thermal resistance, making it suitable for both high and low-temperature applications. It can withstand sudden temperature changes without cracking or shattering.

- Chemical resistance: Borosilicate glass is highly resistant to chemical corrosion, which makes it ideal for storing and transporting a wide range of chemicals, acids, and other reactive substances.

- Transparency: Borosilicate glass is exceptionally transparent, allowing for easy visibility of the contents inside the container. This is particularly useful for laboratory and food storage applications.

- Durability: Borosilicate glass is known for its durability and ability to resist wear and tear, making it a long-lasting choice for containers. It is less prone to scratching and staining compared to some other types of glass.

These features make borosilicate glass containers a preferred choice in a wide range of industries where the properties of glass are required and durability is essential.

Borosilicate glass container offer several advantages, including:

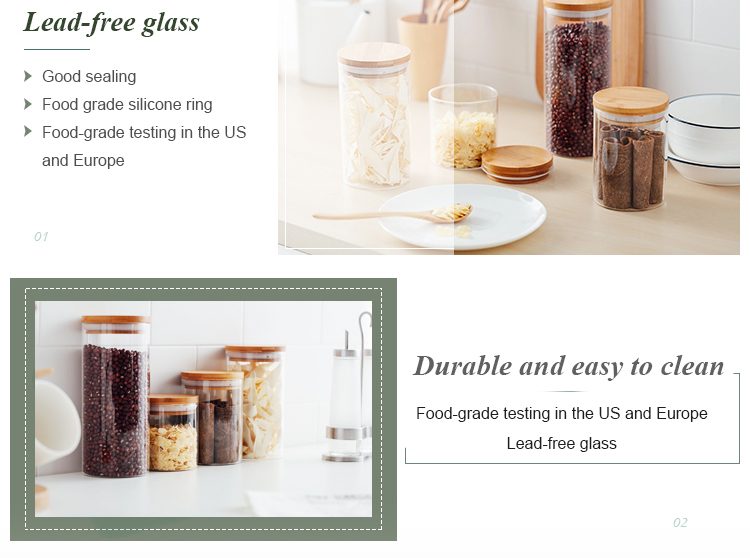

- Non-reactive: It doesn’t react with the substances it holds, maintaining the purity and integrity of the contents. This non-reactivity is critical in applications where the contamination of contents must be avoided.

- Microwave and Oven Safe: Borosilicate glass containers are safe to use in microwave ovens and conventional ovens. They can withstand the temperature changes associated with cooking or reheating.

- Easy to Clean: The smooth, non-porous surface of borosilicate glass makes it easy to clean. It’s dishwasher-safe and can be cleaned by hand without much effort.

- Environmentally Friendly: Borosilicate glass is recyclable, making it an environmentally friendly choice. Recycling helps reduce waste and the need for new glass production.

These advantages make borosilicate glass containers a favored choice in industries where high-performance glass is required and where the safety, durability, and purity of the contents are of utmost importance.

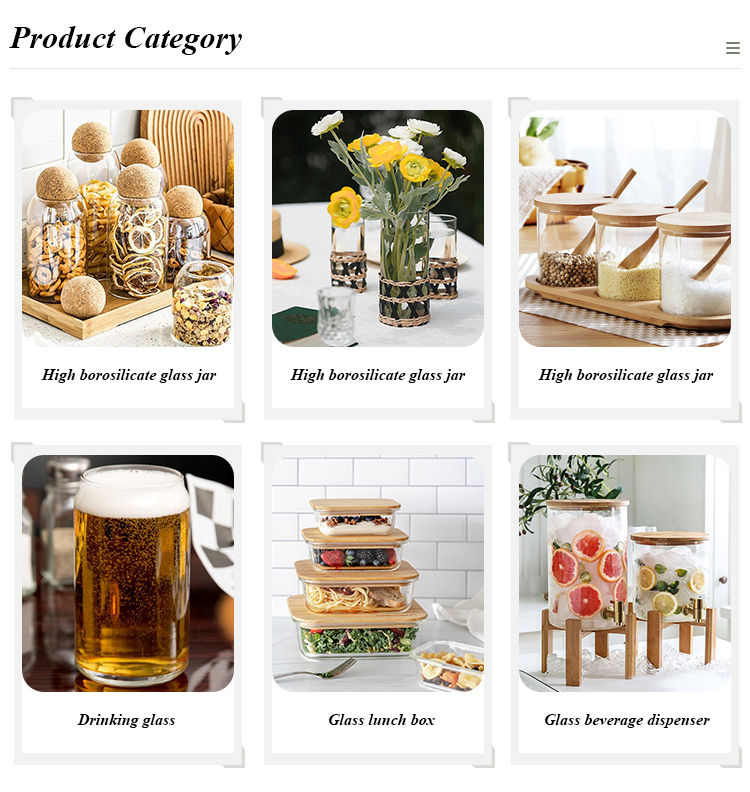

Customizable aspects of borosilicate glass container include:

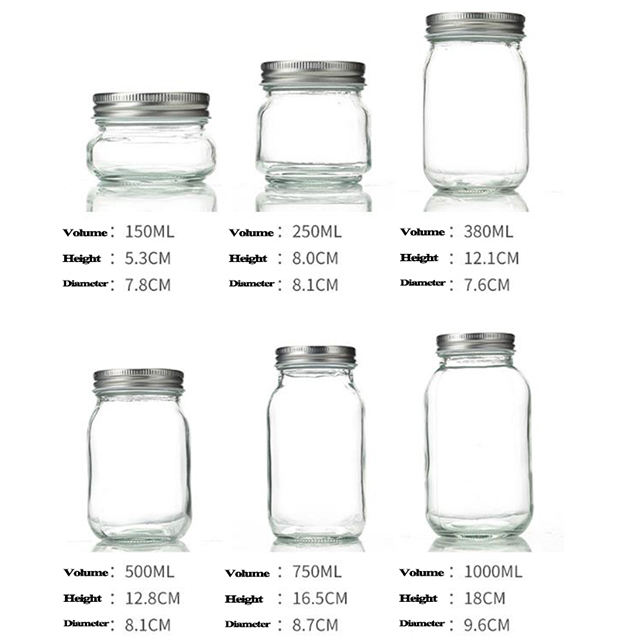

- Size and Shape: Borosilicate glass containers can be produced in various sizes and shapes to suit the intended application. Whether you need a small vial for laboratory samples or a large glass jar for food storage, the size and shape can be customized accordingly.

- Capacity: The capacity of the container can be adjusted to hold the desired volume. This is essential for applications where specific quantities need to be stored or transported.

- Lids and Closures: Custom lids and closures can be designed to match the container. This includes options like screw-on caps, cork stoppers, glass lids, or custom-designed closures that may serve specific purposes.

- Embossing and Etching: Branding, logos, or labels can be embossed or etched onto the glass surface. This allows for custom branding or identification, which is common in the food and beverage industry.

- Color: Borosilicate glass containers can be tinted or colored to achieve a desired aesthetic or to protect light-sensitive contents. Colored glass can be used in cosmetics, perfumes, or any application where UV protection is needed.

- Custom Printing: Custom logos, labels, or decorative printing can be added to the surface of the glass container to enhance its appearance and branding.

These customizable aspects allow borosilicate glass containers to be tailored to specific applications, industries, or personal preferences, ensuring that they meet the unique needs of customers.

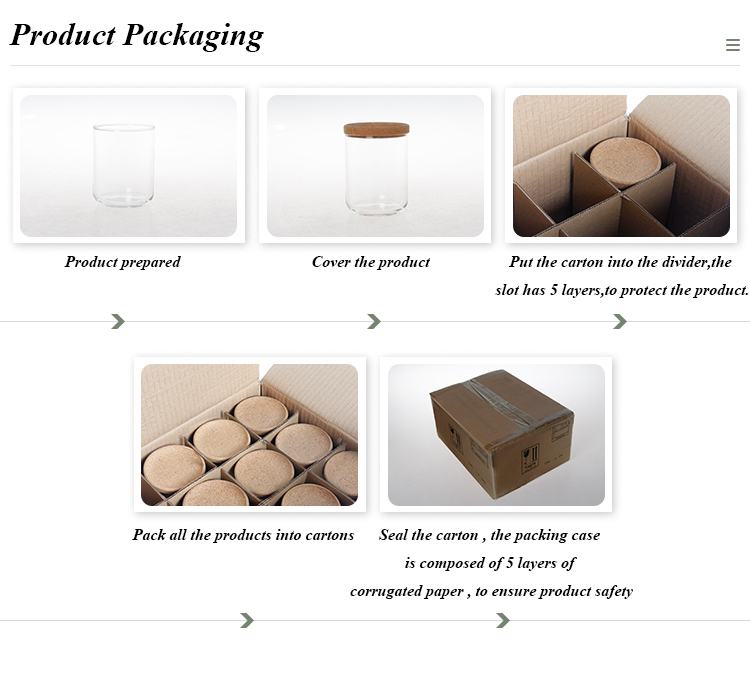

There are several packaging solutions available for borosilicate glass container, including:

- Cartons and Boxes: Glass containers are often packaged in cardboard cartons or boxes. These can be custom-designed to hold multiple containers of various sizes securely. Inserts, dividers, or foam padding may be used to prevent breakage during transit.

- Bubble Wrap or Foam Wrap: Individual glass containers or sets of glassware can be wrapped in bubble wrap or foam to provide cushioning and protection against impact during shipping. This is commonly used in e-commerce and retail settings.

- Dividers and Inserts: Custom-designed dividers or inserts within boxes can compartmentalize the glass containers, keeping them separate to prevent contact and potential damage.

- Cushioned Pouches or Bags: Padded pouches or bags made from materials like microfiber or velvet can be used to protect delicate glass items, such as glassware or glass jewelry.

- Plastic or Acrylic Cases: High-end glass containers or collectibles may be enclosed in clear plastic or acrylic cases. These cases offer visibility and protection, making them suitable for display purposes.

- Custom Cardboard Tubes: For cylindrical glass items, such as vials or glass tubes, custom cardboard tubes with end caps can be used to provide protection and easy handling.

The choice of packaging solution depends on factors like the type of glass container, its fragility, the mode of transportation, and the desired presentation. Custom packaging solutions may also be employed to cater to specific product needs and branding requirements.