The pharmaceutical industry is no stranger to stringent quality standards, precise measurements, and the need for materials that are both chemically inert and thermally stable. In this article, we explore how borosilicate glass tubing plays a pivotal role in pharmaceutical applications and the myriad benefits it brings to the industry.

Applications in the Pharmaceutical Industry

Borosilicate glass tubing has a diverse range of applications in the pharmaceutical sector, owing to its exceptional properties:

1. Drug Containers and Vials: The most common use of borosilicate glass in pharmaceuticals is in the manufacturing of drug containers and vials. These containers must safely store and transport medications without any risk of chemical contamination or alteration. Borosilicate glass’s resistance to chemical corrosion ensures the integrity of the drugs, assuring patients’ safety and efficacy.

2. Laboratory Glassware: Pharmaceutical research and development laboratories rely on borosilicate glassware for a variety of purposes. From reaction vessels and distillation apparatus to high-precision measuring equipment, the glassware’s high thermal resistance and chemical inertness are vital for conducting experiments accurately.

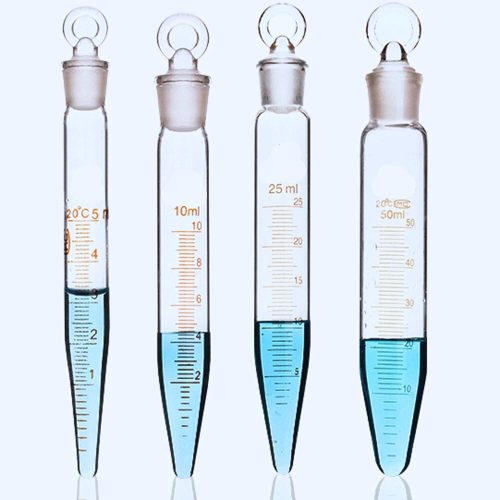

3. Liquid Handling Equipment: Precision in drug preparation and handling is crucial in pharmaceutical manufacturing. Borosilicate glass tubing is used in the production of pipettes, burettes, and other liquid handling equipment, ensuring that measurements are accurate, and substances are not affected by the glass itself.

Benefits of Using Borosilicate Glass Tubing in Pharmaceuticals

Borosilicate glass tubing offers several advantages that align perfectly with the pharmaceutical industry’s requirements:

1. Chemical Resistance: The ability to withstand exposure to a wide range of chemicals without degradation or contamination is a hallmark of borosilicate glass. This is vital when dealing with a variety of chemicals during drug formulation and testing.

2. Thermal Stability: Borosilicate glass can endure high temperatures without undergoing structural changes. This feature is especially beneficial for processes like sterilization, where equipment must be subjected to extreme heat to ensure aseptic conditions.

3. Non-Reactivity: Unlike certain plastic materials, borosilicate glass is non-reactive and does not leach substances into pharmaceutical products. This ensures that the drugs remain uncontaminated and free from any unwanted reactions.

4. Clarity and Transparency: Borosilicate glass tubing offers excellent optical clarity, allowing pharmaceutical professionals to observe and monitor the contents of vials and laboratory glassware with precision. This is vital for quality control and research purposes.

5. Longevity: The durability of borosilicate glass ensures a long lifespan for pharmaceutical containers and equipment. This longevity reduces the frequency of replacement and contributes to cost savings.

6. Regulatory Compliance: The use of borosilicate glass in pharmaceutical applications aligns with regulatory standards. Its well-established history of safety and suitability for drug storage and testing bolsters its appeal in this highly regulated industry.

In conclusion, borosilicate glass tubing is a trusted and indispensable material in the pharmaceutical industry. Its chemical inertness, thermal stability, optical clarity, and durability make it the preferred choice for drug containers, laboratory glassware, and liquid handling equipment. When patient safety, precise measurements, and regulatory compliance are paramount, borosilicate glass tubing shines as a reliable partner in the pharmaceutical world.